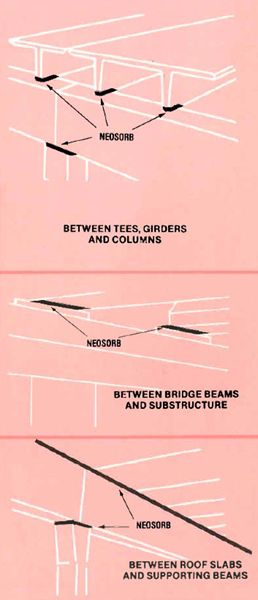

NEOSORB® plain elastomeric (polychloroprene / neoprene) bearing pads are molded or cut to size from larger slabs to provide a low-cost, single element structural bearing. Plain elastomeric bearings are a cost effective option for applications with moderate load transfer and movement requirements. NEOSORB® pads accommodate surface irregularities, vertical load, and rotation through vertical deflection, while longitudinal movement is accommodated through shear deformation. These pads are suitable for use in pre-cast concrete, cast in place concrete, and steel framed structures.

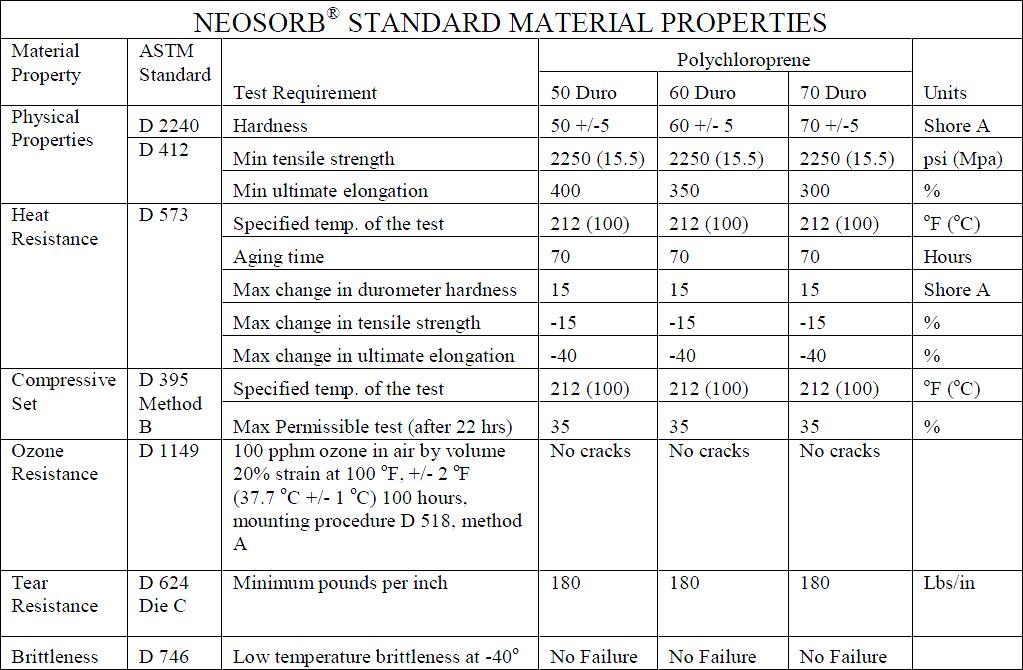

NEOSORB® is available in all 3 standard AASHTO durometers: 50, 60, and 70, widths up to 48″, and lengths up to 49 feet (+/- 1 ft). NEOSORB® is typically available from stock in the following thickness: 1/8″, 1/4″, 1/2″, 3/4″, and 1″.

For pad sizing and selection in the absence of project specifications or owner design criteria, Voss Engineering, Inc. recommends following AASHTO Section 14 Design Specifications for plain elastomeric bearings (PEP).